Product introduction

Candle filtration is a relatively safe and pollution-free filtration method. Candle filters have the characteristics of high precision, easy maintenance, safety and reliability, and high degree of automation. They can be applied to solid-liquid separation filtration in industries such as petroleum, plastics, electroplating, chemical industry, ceramics, pharmaceuticals, and sugar production.

Candle filtration has gradually replaced pressure filtration and bag filtration as the mainstream filtration method, and the repeated use of filtration media has saved a lot of filtration consumables; The cylinder is tightly sealed to ensure no leakage during the production process; The full process control of microcomputer automation not only maintains the continuity of enterprise production, but also greatly reduces the risk of production accidents while improving production efficiency and saving labor.

Product structure

Candle filter is an automated pressure filtration device, mainly composed of a cylinder, filter element, filter cloth, filter aid, computer control system, and accessories. Other auxiliary equipment includes an air compressor, pressure sensor, etc. The material of the cylinder and filter element is mainly stainless steel (304/316/321), carbon steel, titanium, and the material of the filter cloth is mainly PP (polypropylene), PE (polyester), PPS (polyphenylene sulfide), PTFE (polytetrafluoroethylene), nylon fiber, etc. The filter aid is configured according to the filtration standards in the production process, mainly including activated carbon, diatomaceous earth, etc. Candle filter, as a large-scale equipment on the production line, is commonly referred to as candle filter.

Operational principle

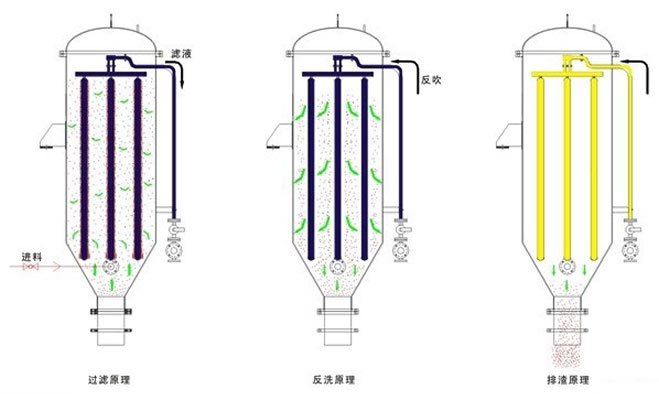

The cylinder of the filter is equipped with one or more filter elements, and the filter element is covered with a special filter cloth selected according to the characteristics of the raw material liquid (some special raw material liquids require the addition of filter aids, such as activated carbon, diatomaceous earth, etc.). When the liquid passes through the filter cloth, solid substances in the liquid will gradually accumulate on the surface of the filter cloth. When these solid substances reach a certain thickness, a so-called "filter cake layer" is formed. Due to the small gaps between the particles in the filter cake layer, the escape of particle impurities in the liquid is hindered, which makes the filtrate clear and achieves the required filtration effect for production. So candle filters are also known as cake layer filters.

After a period of normal filtration, if the filter cake layer exceeds a certain thickness, the rate of filtrate passing through the filter cake layer decreases, and the filtration efficiency deteriorates. Therefore, it is necessary to remove the "filter cake layer". At this time, the system will perform a reverse blowing and cake removal operation based on the signal provided by the pressure sensor, open the valve at the bottom of the cylinder to discharge slag, and then rebuild a new "filter cake layer" to start a new round of filtration cycle.

The thickness control of filter cake layer, cleaning of filter residue, reconstruction of new filter cake layer, and monitoring of filtrate quality are the four major technical points and difficulties of candle type (filter cake layer) filters.