Product introduction

The "three in one" filtration, washing, and drying process equipment is a new generation of solid-liquid separation technology that has gradually been promoted and used in China since the 1990s. RUNLV's multifunctional filtration, washing, and drying unit can complete the three process of filtration, washing, and drying of materials in a closed container equipment, greatly improving equipment utilization. It avoids environmental pollution and material pollution, reduces material transportation losses, saves solvent usage, and is suitable for intermittent batch production.

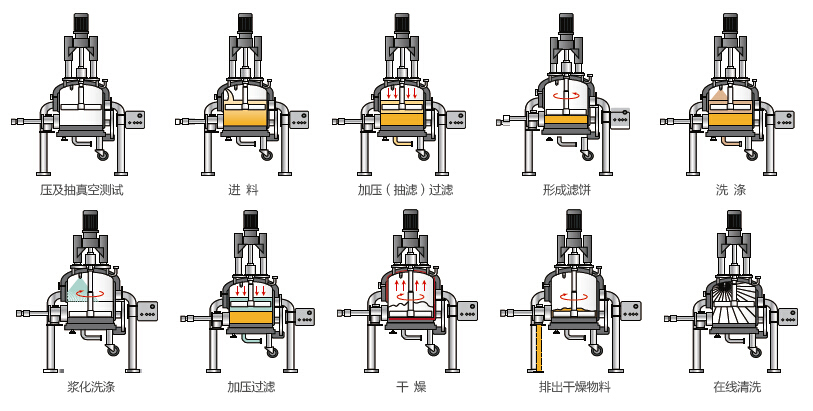

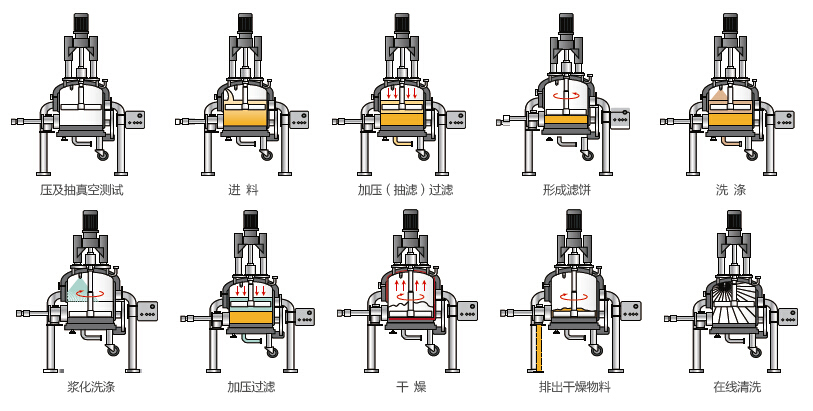

Operational principle

Filtering stage: Separation of the filter cake and mother liquor of the product. The thickness of the filter cake can reach 600mm.

Washing stage: further purification of filter cake, cleaning of residual mother liquor, and pre dehydration. Mix the filter cake and washing solution layer by layer through a lifting stirrer to form a slurry, and the suspension filter cake is thoroughly washed.

Drying stage: Dehydration and drying treatment of filter cake. While the filter cake is loosened layer by layer by the agitator, the equipment sidewalls, bottom of the filter plate, and moving stirring blades simultaneously heat the filter cake. The moisture evaporates rapidly to achieve the drying effect. The evaporation speed is accelerated through the vacuum method inside the equipment, and the evaporated moisture is carried away by adding processed hot nitrogen and other media, accelerating the drying of the material and improving the drying effect.

Unloading stage: The dry material is automatically discharged from the side outlet through the reverse rotation of the S-shaped mixing slurry.

Product advantages

Choose appropriate materials for different media

Suitable for closed production of materials

The applicable range of operating temperature and pressure is wide

Reduce investment costs

Reduce labor force

High utilization rate

The product has a wide range of applications

The three wastes can be completely recycled

Equipment characteristics

The RUNLV multifunctional filtration unit operates continuously throughout the entire process of filtration, washing, and drying within the same container.

Operate under pressure or vacuum to achieve solid-liquid separation.

The distribution of filter cake is uniform, and the solid-liquid separation effect is good.

The lifting of the RUNLV hydraulic control mixing system maximizes the space for solid materials during filtration.

The lifting and stirring of the stirring blades ensure that the filter cake and cleaning solution are fully mixed during cleaning, and the filter cake is thoroughly washed.

Greatly shorten the drying time and improve efficiency.

The liquid outlet valve has multiple controls, and the solid discharge system automatically discharges, reducing labor intensity.

Can be cleaned and sterilized online; The entire operation can be carried out under inert gas protection, which is safe and reliable.

The RUNLV filter bottom plate is detachable, which helps to thoroughly clean the equipment. It is suitable for the production of sterile raw materials and fully complies with GMP and FDA production requirements.

Standard device

drive system

Sealing system

Heating and stirring system

Sampling valve

Discharge device

Online cleaning and sterilization system

Material washing device

Dry dust filtration system

Lift drive system

intelligent control system

Technical parameter

|

Standard model |

DN500 |

DN600 |

DN800 |

DN1200 |

DN1400 |

DN1600 |

DN2000 |

DN2300 |

DN2800 |

DN3000 |

DN3200 |

Nominal filtration area

(㎡) |

0.19 |

0.28 |

0.5 |

1.0 |

1.5 |

2.0 |

3.0 |

4.0 |

6.0 |

7.0 |

8.0 |

Inner diameter

(mm) |

500 |

600 |

800 |

1200 |

1400 |

1600 |

2000 |

2300 |

2800 |

3000 |

3200 |

Nominal volume

(m³) |

0.4 |

0.26 |

0.53 |

1.36 |

1.19 |

2.99 |

5.06 |

6.76 |

10.8 |

14.8 |

16.8 |

Cylinder height

(mm) |

600 |

750 |

900 |

950 |

1100 |

1200 |

1200 |

1250 |

1250 |

1550 |

1550 |

Filter cake height

(mm) |

120 |

120 |

200 |

250 |

300 |

350 |

400 |

450 |

450 |

600 |

600 |

Blade lifting height

(mm) |

150 |

150 |

300 |

300 |

350 |

400 |

450 |

500 |

500 |

550 |

550 |

Mixing motor power

(KW) |

2.2 |

3.0 |

5.5 |

7.5 |

11 |

15 |

18.5 |

18.5 |

22 |

37 |

45 |

Net weight of equipment

(Kg) |

1350 |

1560 |

2230 |

4300 |

5890 |

6630 |

11350 |

13850 |

16300 |

18650 |

21230 |

Total height of equipment

(mm) |

2560 |

2890 |

3130 |

3900 |

4360 |

4680 |

5150 |

5280 |

5520 |

5750 |

5850 |

Application area

Filtering methods: filtration, separation, screening, enclosed, pressure filtration, suction filtration, multifunctional, intelligent automatic, online cleaning and sterilization.

Filtering purpose: Filter crystalline or granular materials, filter required liquids, wash required solid materials, and dry required solid materials.

Application industries: pharmaceutical technology, food and beverage, fine chemicals, petrochemicals, pesticides, printing and dyeing, papermaking, etc.

Applicable materials: antibiotics, penicillin, proteins, polymers, vitamins, citric acid, pigments, nickel production, recovery of various precious metal catalysts, sugar production, titanium dioxide production, melamine production, chlor alkali industry production, glyphosate decolorization and decarbonization, activated carbon filtration, polycrystalline silicon powder recovery, and waste acid (hydrofluoric acid and nitric acid) filtration.